Reliable Bottling Lines With Filling Machine Solutions

drop us a line. MEET YOUR NEEDS. liquid filling MACHINERY. Elevate your production line with our versatile and dependable equipment, designed to effortlessly cater to every filling requirement, from fizzy sodas to tranquil still water. Carbonated Beverage Filling Machine If you want to enhance your production and bottling... Juice Filling Machine The innovative bottle wash system of the juice filling... Water Filling Machine iBottling, the bottle filling machine manufacturer,... Water Filter / Water Treatment Factory layout of 10,000bph soda drink filling line for... Glass iBottling’s SLWG series 3-in-1 glass bottle filling and... Oil E5L series industrial oil filling machines expertly bottle... About China leading machinery supplier, we specialize in bottle... Canning Machine Steplead’s YPO series soda and beer canning machines...

Water Filling Production Line: Efficient, Safe, and Stable ...

The water filling production line is a crucial equipment in the modern chemical industry, used for efficient, safe, and stable filling and packaging of water or other liquid products.

The 4 Elements of a Basic Liquid Fill Production Line

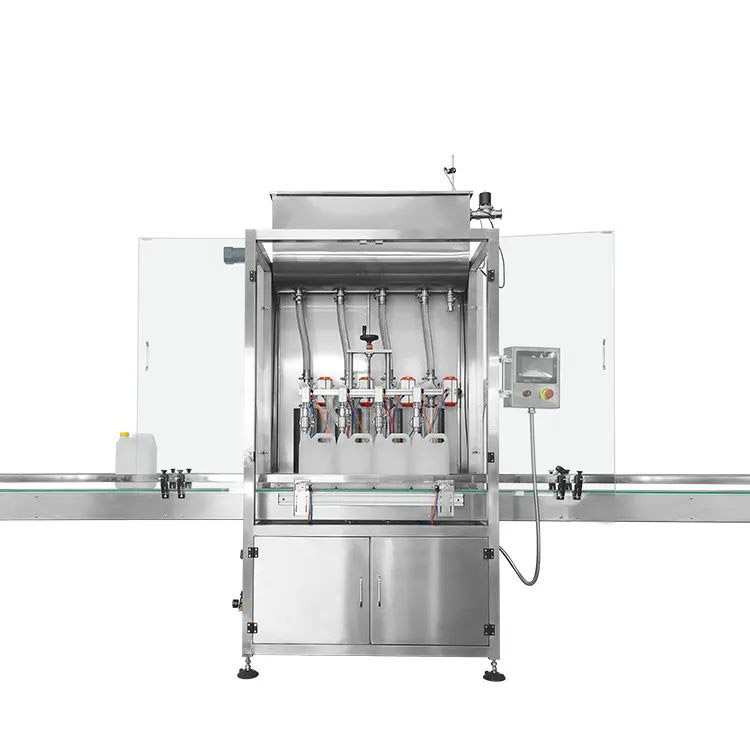

You can customize your production line to fit your needs in many ways, but the basic liquid fill production line will contain the following four elements. Liquid Filling Machine. Of course, liquid fillers are the primary components of any successful liquid fill production line. Whether you are filling thin, watery liquids, creams, or gels, you ...

What Is The Bottled Water Production Line Flow Chart

Description. The fully automatic bottle blow molding machine is suitable for blowing all kinds of plastic containers and beverage bottles using PET raw material. It is widely used in the production of gas-containing beverage bottles, pure mineral water bottles, juice bottles, oil bottles, cosmetic bottles, and more.

How to select, operate and maintain beverage fillers

Observations, special studies and compliance evaluations have led to the conclusion that the filling machine is the kingpin of practically every beverage production/packaging line in any segment of the industry. Visits to wineries, distilleries, breweries, soft drink facilities, as well as juice, water and specialty beverage facilities, have provided substantial evidence that many portions of ...

Carbonated Beverage Production Line CSD Filling Lines

Also known as sparkling drink production lines or CSD (carbonated soft drink) processing lines, these complete manufacturing solutions allow beverage manufacturers to achieve the ultra-high outputs needed for mass production of soda, carbonated juices and flavored sparkling waters.

Liquid Filling Lines, Bottle Filling Line System - VKPAK

The choice of filling system or filling line depends on the physical state of the product, the packaging container of choice, the desired mass or volume per container, the required production volume, and considerations of sterilization and safety. VKPAK mainly offers filling lines for liquid bottles.

Complete Bottled Water Filling Production Line | Luye Machinery

The complete bottled water filling production line is a set of equipment system for automatic filling, sealing and packaging bottled water. The production line consists of multiple steps and machines that work together to ensure that each operation is done efficiently, hygienically and precisely.

Carbonated Beverage manufacturing process flow

Carbonated Beverage manufacturing process flow. The manufacturing process for carbonated beverages involves several key steps to create the characteristic fizz and flavor while ensuring product safety and quality. Source raw materials like water, sugar, flavorings, acids, and carbon dioxide (CO2) gas. Purify and treat the water source to remove ...

Small Flavored Water Production Line Manufacturing Plant

Product Description. Application: juice, milk, vitamin drinks, functional beverage with particles, flesh, pulp, fruit pieces, etc. Suitable for: PET bottles with all volumes and shapes. Filling system: 10,000 BPH For 500 Ml Juice Plant Manufacturer Juice Factroy Machine. Production capacity: 2,000BPH–20,000BPH (500ml) Technical characteristics. 1.

Contact Us Now