JBT¡¯s Filling and Closing technology for liquid dairy ...

SCM undergoes thermal pasteurization before filling and seaming of the cans. The high sugar concentration in sweetened condensed milk increases the osmotic pressure to such a level that most of the microorganisms are destroyed. This product is, thus, not heat-treated after packaging as its high sugar content preserves it for a long shelf-life.

Milk production and processing equipment | Tetra Pak Global USA

Flexible aseptic dosing - functional ingredients are injected with high precision into the base product after the final heat treatment, just before filling. Standardization When standardizing dairy products, the cream and milk are first separated on a dairy line.

High precision condensed milk filling machine with heat and ...

The manufacture of condensed milk, using these two methods, has This product is not heat treated after packaging as its high sugar content The first stage, in both cases, comprises precision standardization of the milk fat Aseptic filling found in Chapter , Centrifugal machines and milk fat standardization systems.

CONDENSED MILK | Dairy Processing Handbook

Pre-treatment is essentially for the final quality and includes standardization of fat content, solids-non-fat, as well as heat treatment. Standardization. Condensed milk is marketed with a stipulated content of fat and dry solids. The figures vary with the applicable standard, but are normally 7.5 % fat and 17.5 % solids-non-fat.

Tetra Therm? Aseptic VTIS direct UHT processing

System for continuous direct UHT treatment of liquid food products under aseptic conditions Capacity 2,000 l/h to 30 000 l/h (variable capacity 1:2 is standard) Applications Milk, enriched milk, cream, soymilk, formulated dairy products, ice-cream mix, extended shelf life (ESL) products, dairy desserts, non-dairy cream, and smooth soups and sauces.

How Is Condensed Milk Made: Condensed Milk Manufacturing ...

1. Whole Milk or Water. In the modern approach, the process begins with either whole milk or water as the base. 2. Reconstituted Concentrated Milk. To achieve the desired consistency, various ingredients are added, such as skim milk powder (SMP), full cream milk powder, butter oil, and sugar. This step results in reconstituted concentrated milk. 3.

Efficient Tin Can Filling and Sealing Machine for Condensed ...

This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action. Accurate measurement: adopt servo control system, ensure the piston can always reaches constant position.

Filling & Closing Packaging Machines | FoodTech - JBT

You, too, can profit from our well-designed, heavy-duty filling and closing equipment. You¡¯ll come to love the easy cleanability, high operating efficiency, lower per-unit cost, and operator safety features. Plus ¨C with the happiness of your customers in mind ¨C JBT solutions provide the optimal mix of product quality and product safety.

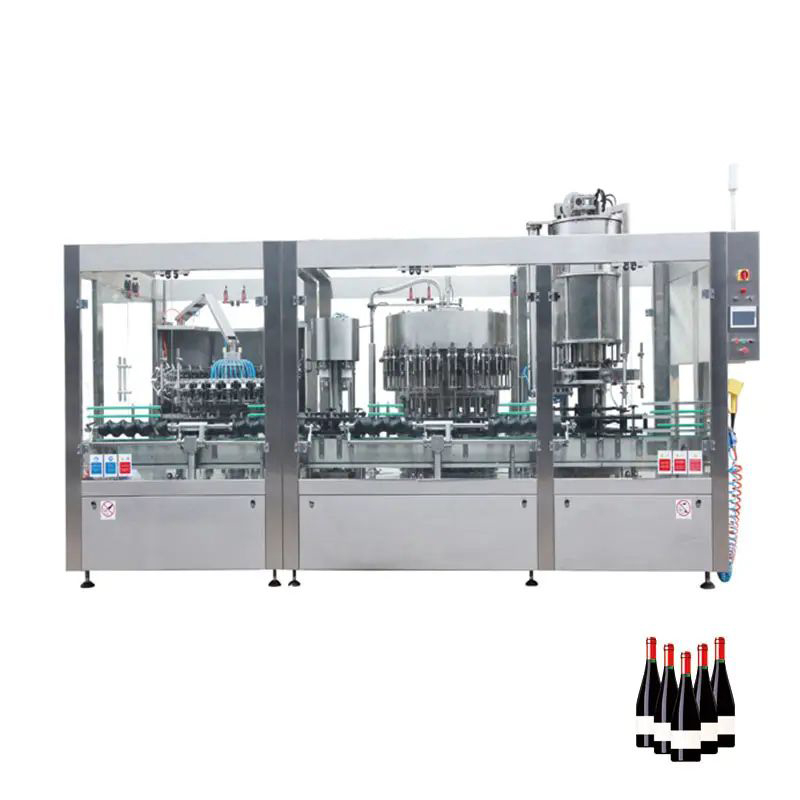

Can Filling Machine Production Line Equipment | Luye Machinery

Filling Part: 1.304/316 Stainless steel high precision filling nozzle 2.Filling volume adjustable in fine rank, same liquid level after filling 3.All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean 4.304/316 stainless steel filling pump 5.Efficient spray nozzle rinse thoroughly and save water for ...

Small Capacity Automatic Sweetened Condensed Milk Filling Machine

Capping heads. The capping machine is the highest precision in 3-in-1 unit machine, on the reliability of equipment operation, has enormous influence on the defective rate of the product.Introduced the world's most advanced Italian AROL capping machine technology, combining with the filling machine production experience improvement, and ask college of Shanghai Jiao Tong university mechanical ...

Contact Us Now